DAI NGHIA SATISFACTION CUSTOMERS WITH 5 QUALITY GOALS

- Stability quality

- On time delivery

- Complete service

- Regular improvement

- Effective competition

QUALITY MANAGEMENT SYSTEM

Enterprise Resource Planning (ERP) system helps to improve overall productivity and leverages quality management, specifically:

- Organize the supply chain from purchasing, ordering process from customers, production and inventory.

- Complete work on time with better supervision.

- Improve customer service when making quick decisions with easy-to-use reporting and analytics.

- Control resources, cash flow and accounting.

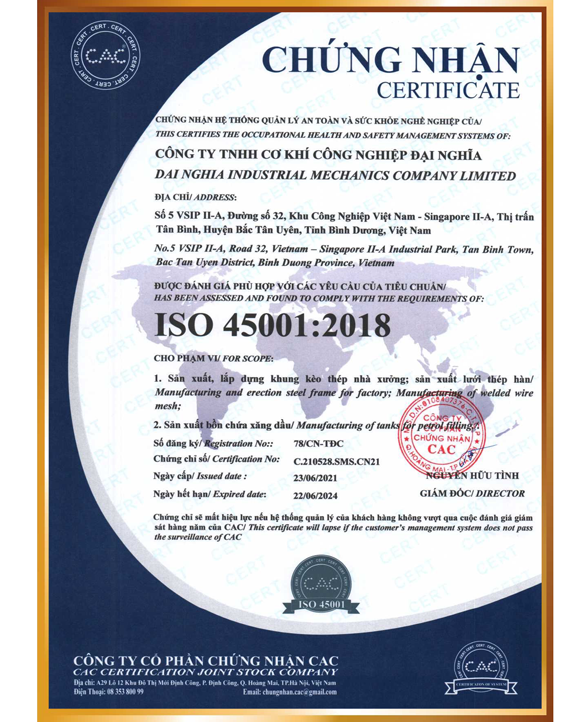

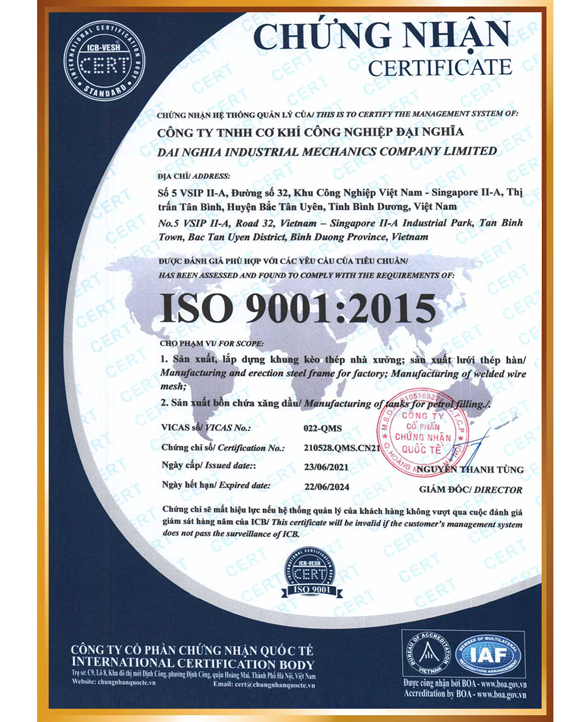

ISO 9001:2008 QUALITY MANAGEMENT SYSTEM

Demonstrating Dai Nghia's ability to provide products that meet customer needs, applicable laws and regulations.

Increase customer satisfaction through effective application of the system including processes for continual improvement of the system and to ensure that customer needs and current legislation are met.

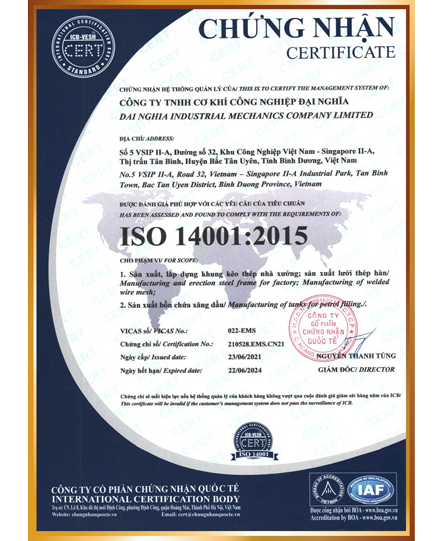

ISO 14001:2004 ENVIRONMENTAL MANAGEMENT SYSTEMS

In the spirit of “IMPROVEMENT AND ENVIRONMENTAL PROTECTION”, we are committed to building, implementing and maintaining the ISO 14001:2004 environmental management system based on the following basic principles:

- Strictly comply with legal regulations and other requirements related to the company's environmental aspects.

- Always consider improvement in all activities, actively implement improvement goals and programs to perfect the environmental system.

- Protect the environment by effectively controlling waste, resources and environmental incidents through implementing appropriate operating controls and effective monitoring.

- Strengthen training and environmental information to employees in the company and stakeholders, ensuring resources to meet the requirements of the environmental management system.

- An Lac wishes to contribute to building a better living environment.

TRACKING, MONITORING & IMPLEMENTING 5S WILL

Organize the workplace to limit the waste (time, resources and people) that is the result of a poorly organized workplace.

TPM (Total Productive Mainternance) - Total Productive Maintenance

Proactive and preventive maintenance to maximize equipment uptime.

Root Cause Analysis Ensure the problem is really eliminated by properly addressing the root cause of the problem after answering the why question five times to uncover the real underlying problem.

KPI (Key Performance Indicator) – Indicator to measure job performance

Work is designed with metrics to track and encourage employee progress towards Dai Nghia's key goals