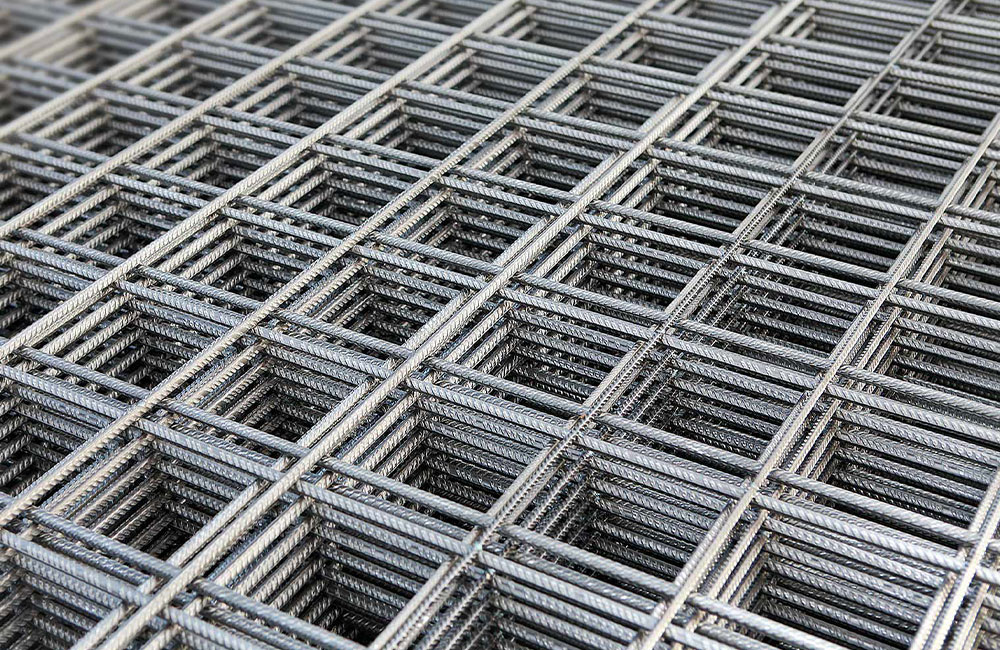

Skipping the steps of manual wire mesh weaving, we believe Dai Nghia's products will help contractors speed up the construction progress of items related to Welded Wire Mesh, contributing to speeding up the progress of the work.

Dai Nghia welded wire mesh products apply TCVN 9391:2012 in production, quality is strictly controlled in all stages of production with a team of highly qualified QC engineers and skilled workers.

Bringing friendly, accurate, cost-effective, cost-optimized construction solutions to customers.

Products

Production Process

1. Check certificates

2. Check CO/CQ

1. Check steel grade

2. Check steel diameter

1. Check steel surfafe after stretching

2. Check steel diameter after stretching

3. Check steel intensity after stretching

1. Check steel length

2. Check straightness

3. Check surface, bonded

1. Check the dimension of drawing

2. Visual checking: welded joint and the square of welded mesh.

1. Check the length of excess head and the angle in comformity with shop drawing.

1. Overall checking for welded mesh

2. Check stamp and quantity as order

3. Pack welded mesh in according to weight of product

Advantages

Steel welded wire mesh is automatic processing by a production line, so the mesh step spacing is uniform, ensuring technical and aesthetic requirements..

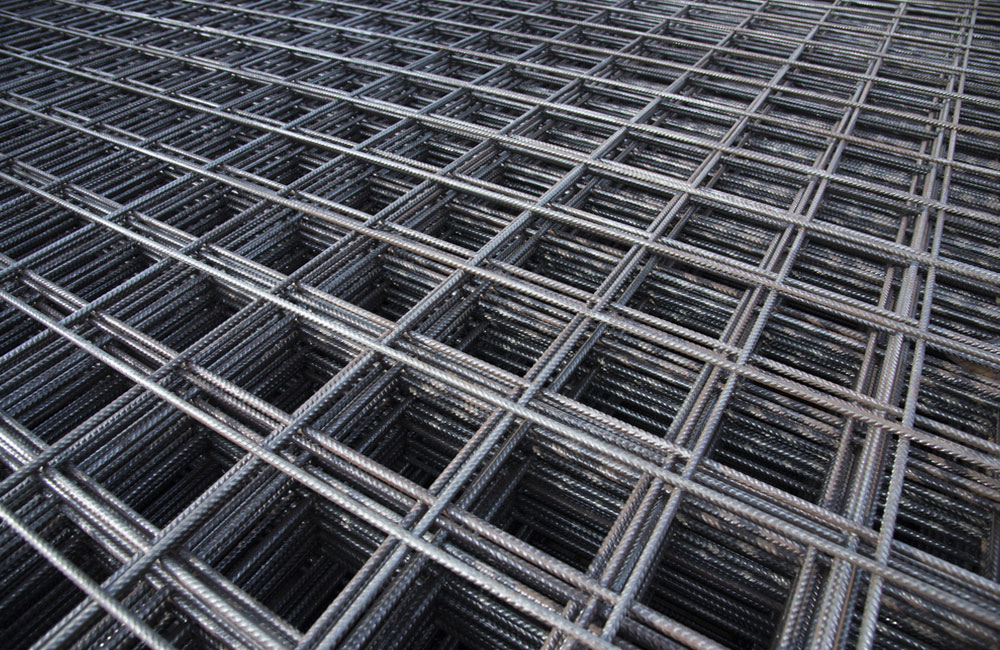

The transportation, installation or replacement of steel welded wire mesh becomes extremely simple and convenient.

Using steel welded wire mesh for concrete floor items are reduces costs such as labor fees, maintenance fees, site supervision, construction site costs, speeding up the progress...

Not only has the square specification, but also the pre-fabricated steel welded wire mesh is designed and fabricated as specification, design drawing, and customer requirement.

Steel welded wire mesh is manufactured and stored in the factory, ensure the quality of the product is not affected by weather factors. That helps the contractor planning to use the construction site areas more efficiently, avoiding loss and drain of materials at the construction site.

Before processing welding the wire mesh, steel wires are stretched to increase the carrying strength and reduce the diameter of the wire steel, therefore can reduce the weight of steel, but the strength of steel wire mesh is ensured according to Vietnamese construction standards.

Steel welded wire mesh is pre-fabricated at the factory and transported to the construction site, therefore can reduce the construction time is shortened to 1/3 compared to the construction of traditional to quickly put the works into use.