The factory is located at VSIP II IP, Binh Duong Province where has a lot of high-skill labors in steel fabrication and convenient traffic.

• The distance is around 1 hour traffic from the airport, sea port

• Production machinery is new, layout is arranged tidily.

CAPACITY

• Area: 35.000m2

• Steel structure: 2.500 ton/month

• Steel welded wire mesh: 1.500 ton/month

• Purlin: 500 ton/month

• Sheeting panel: 200.000 m2/month

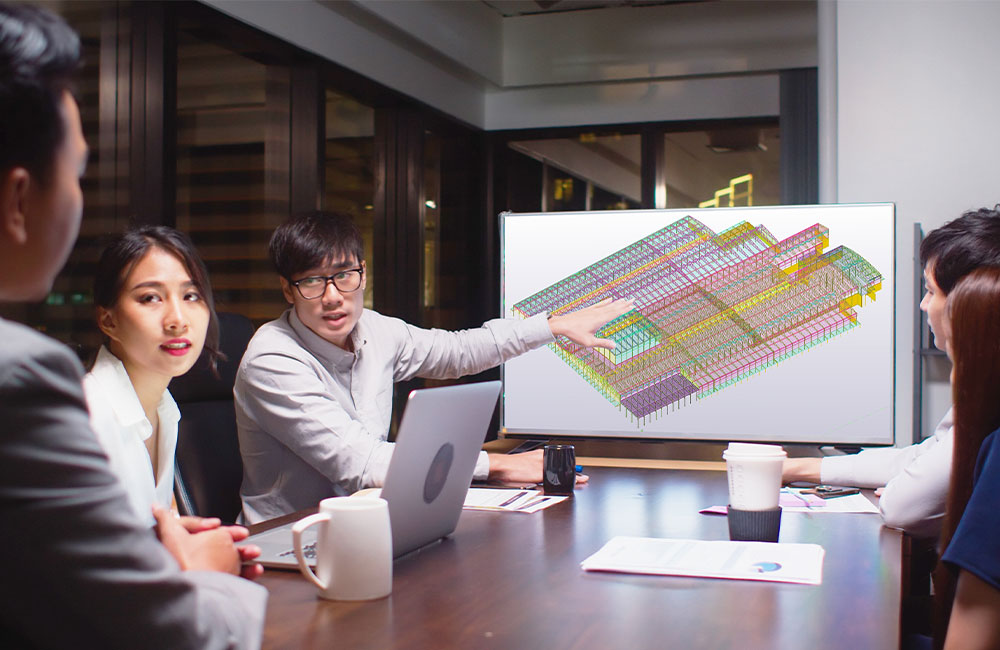

We turn the ideas, plans on the desks and drawings of customers into works with real shape and shape based on the hands and brains of a team of professional staff, experienced in supervision and execution. exam, management.

We have the ability to design and build different construction items through the professional support of a team of engineers, consultants and project managers.

Through the consulting process, Dai Nghia Steel helps customers have an overall picture of the finished product through the most optimal solutions. Besides, we always care about the ideas and wishes of customers and develop products according to the most professional design process.

Steel Structure Brochure

To better understand Dai Nghia's product & service solutions, capabilities and service commitments, please view our Steel Structure Brochure.

Design Process

From 3D model Tekla, the engineer updates drawings for each component and put them on the system to make the input of production.

Analytic the detail of quantity, send finalize the quotation to customer to sign contract.

Submit the documents to competent authorities to approve the design.

Implementation of the architecture and structure design based on the solution has analysis with customers.

Consider and give solutions with optimal design to save cost but ensure the function, quality and safety are no compromise

Based on preliminary information. The engineering team discusses together to give the solution with optimized design to save cost for customers.

Production - Quality Control Process

1. Check certificates

2. Check CO/CQ

1. Check steel grade

2. Check steel diameter

1. Check steel surfafe after stretching

2. Check steel diameter after stretching

3. Check steel intensity after stretching

1. Check steel length

2. Check straightness

3. Check surface, bonded

1. Check the dimension of drawing

2. Visual checking: welded joint and the square of welded mesh.

1. Check the length of excess head and the angle in comformity with shop drawing.

1. Overall checking for welded mesh

2. Check stamp and quantity as order

3. Pack welded mesh in according to weight of product

EQUIPMENTS

With modern machinery and equipment to meet the increasing demands of customers, the production capacity of Dai Nghia factory is as follows:

With a system of packing, lifting goods and specialized crane trucks team, Dai Nghia ensures delivery to customers with the following criteria:

- Goods that are hoisted or arranged up and down to the vehicle are not warped or deformed

- Quality monitoring system through each step of operation

- Timely delivery, on time schedule of the project

- Delivery at the construction site